In Fire Dynamics Simulator (FDS), a mesh sensitivity study is the process used to verify that simulation results are controlled by the modeled fire physics rather than by the numerical resolution of the computational grid. This step is essential for any simulation intended to support engineering decisions, because an inadequate mesh can produce apparently reasonable results that are in fact driven by numerical artifacts.

Unlike steady-state CFD methods, FDS is based on Large Eddy Simulation (LES). This has important implications for how mesh sensitivity should be understood and evaluated.

Table of Contents

Mesh Sensitivity in FDS

In CFD approaches based on Reynolds-Averaged Navier–Stokes (RANS), mesh refinement is typically associated with numerical convergence: as the grid becomes finer, the solution approaches a single, well-defined result.

This is not the case in FDS.

FDS is based on Large Eddy Simulation (LES), which explicitly resolves large turbulent structures while modeling only the smallest scales. Fire-driven flows are inherently unsteady and chaotic, so the instantaneous solution in FDS never converges in a classical sense. Even with very fine meshes, velocity, temperature, and species fields continue to fluctuate over time.

For this reason, mesh sensitivity in FDS should not be interpreted as a search for a unique numerical solution. The practical objective is instead to verify that further mesh refinement does not produce meaningful changes in the quantities of interest used for engineering evaluation. When this condition is met, the solution can be considered sufficiently resolved for its intended purpose.

What LES Means in Practice for FDS Users

In LES, the computational mesh acts as a spatial filter:

- flow structures larger than the cell size (dx) are resolved explicitly;

- flow structures smaller than dx are modeled through a subgrid-scale turbulence model.

As a direct consequence, mesh resolution in FDS controls how much of the turbulence is resolved rather than modeled. Coarse meshes increase numerical diffusion and tend to smooth the flow, reducing plume entrainment, mixing, and velocity fluctuations. Finer meshes resolve a larger portion of the physically relevant turbulence, producing more realistic plume behavior and stratification.

Therefore, changing the mesh resolution in FDS is not merely a numerical refinement—it directly affects the physics that the simulation can represent. A mesh sensitivity study is essentially a check that the most important flow structures influencing the results are adequately resolved.

The Characteristic Fire Diameter (D*)

In FDS, the initial selection of mesh resolution is often guided by the characteristic fire diameter, D*, a length scale that relates the fire heat release rate to buoyancy-driven flow behavior. Rather than defining an absolute cell size, D* is used through the non-dimensional ratio D*/dx, which indicates how many computational cells span the characteristic diameter of the fire plume.

The characteristic fire diameter is defined as:

where:

- is the total heat release rate of the fire,

- is the ambient air density,

- is the specific heat of air,

- is the ambient temperature,

- is the acceleration of gravity.

Commonly used reference ranges in FDS practice are:

- D*/dx ≈ 4: very coarse resolution, suitable only for exploratory simulations.

- D*/dx ≈ 10: generally accepted for engineering analyses such as smoke movement and tenability.

- D*/dx ≥ 16: recommended for validation studies or safety-critical applications.

The D*/dx ratio primarily assesses the ability of the mesh to resolve the buoyant fire plume and its entrainment. As the ratio increases, plume dynamics are increasingly resolved explicitly rather than dominated by numerical diffusion and subgrid-scale modeling.

However, D*/dx should not be interpreted as a universal measure of mesh adequacy. It does not ensure sufficient resolution of wall flows, vent jets, ceiling jets, or compartment-scale circulation. For this reason, D*/dx should be viewed as a necessary but not sufficient condition: a rational starting point for mesh design that must always be complemented by a systematic mesh sensitivity study focused on the specific quantities of interest.

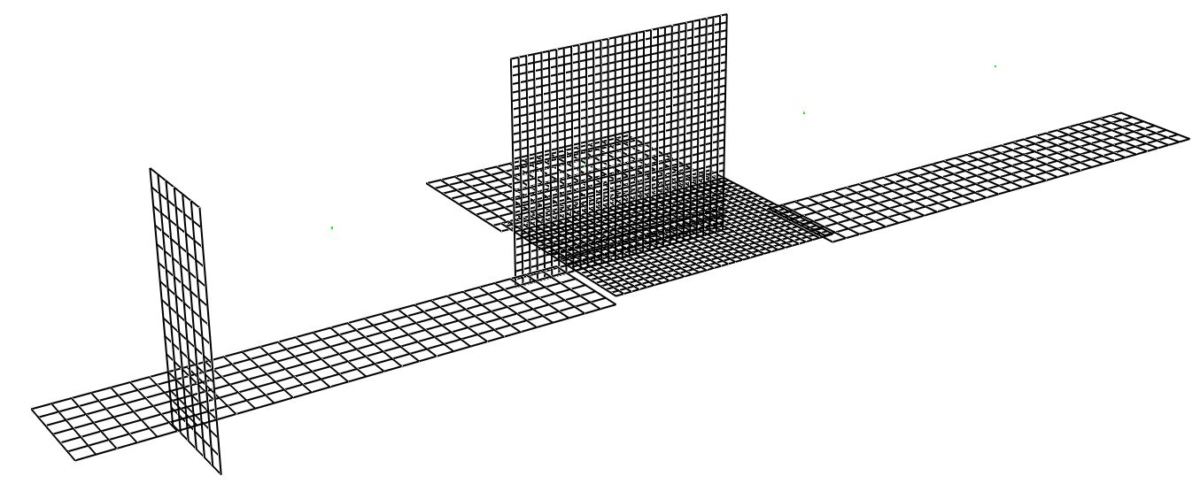

The Three-Grid Strategy

A structured mesh sensitivity study in FDS is typically performed using at least three meshes of increasing resolution: coarse, medium, and fine. All other model inputs must remain unchanged.

Mesh refinement is often performed by reducing the cell size uniformly by a constant factor. When the cell size is halved in each spatial direction, the total number of cells increases by a factor of eight, which significantly increases computational cost. For this reason, full factor-of-two refinement is often impractical for large domains.

In practice, what matters is not the absolute refinement factor but that it is large enough to reveal genuine resolution effects. Refinement ratios smaller than about 1.3 may produce changes that are difficult to distinguish from numerical noise or natural turbulent fluctuations. A refinement ratio of 1.3 or greater is generally sufficient to identify whether changes in results are driven by mesh resolution rather than randomness in the flow.

Choosing and Evaluating Quantities of Interest

Mesh sensitivity must always be evaluated using clearly defined quantities of interest (QoI). In FDS, these may include temperatures, smoke layer height, species concentration, mass flow rates, or velocities.

Single-point measurements, such as the output of an individual thermocouple, are highly sensitive to local grid alignment and transient turbulent structures. As a result, they are poor indicators of mesh independence.

Instead, mesh sensitivity studies in FDS should rely primarily on spatially integrated or averaged quantities, such as:

- mass flow through vents or openings,

- average layer height in a compartment,

- volume-averaged temperature or species concentration.

These quantities are far more robust and provide a clearer indication of whether the overall flow behavior has stabilized with respect to grid refinement.

Interpreting the Results

Different outputs exhibit different sensitivity to mesh resolution. Global quantities such as plume centerline trends or average layer height often stabilize relatively quickly. In contrast, quantities related to entrainment, mixing, and local velocities are much more sensitive and may continue to change with refinement.

In engineering practice, mesh independence is commonly argued when the difference between results obtained on the medium and fine meshes falls within an acceptable tolerance, typically on the order of 1–5%, depending on the application and required safety margin.

Formal approaches such as the Grid Convergence Index (GCI) exist, but they are rarely applied rigorously in FDS fire modeling due to the transient and highly turbulent nature of fire-driven flows. In most cases, mesh sensitivity in FDS remains a structured engineering judgment rather than a purely mathematical procedure.

Final Remarks

In FDS, a mesh sensitivity study is not about proving numerical convergence, but about demonstrating that the mesh resolution is adequate for the physical phenomena and engineering quantities being evaluated. Understanding the implications of LES, using D*/dx appropriately, refining the mesh systematically, and interpreting results based on robust quantities of interest are all essential to producing reliable and defensible fire simulations.